The questions below have been asked by the local community during open days , one-on-one interviews, information sessions and meetings.

Please click on a question below to display the answer

Who prepared the Environmental Impact Statement (EIS)?

The EIS has been prepared by RW Corkery & Co Pty Limited who are a leading provider of geological and environmental consulting services to the mining, quarrying and waste management industries both in Australia and internationally.

Other contributors to the EIS are listed below:

| SLR Consulting | Noise, Vibration & Blasting |

| Richard Lamb & Associates | Visual Amenity |

| Ramboll Environ | Air Quality |

| EnviroKey | Terrestrial Ecology |

| Cardno | Aquatic Ecology |

| McKenzie Soil Management | Soils & Land Capability |

| Barnson | Site Access |

| The Transport Planning Partnership | Transport |

| EnRiskS | Health Risk & Lead Management |

| Landskape | Aboriginal & Cultural Heritage |

| WRM Water & Environment | Surface Water |

| Jacobs | Groundwater |

| Umwelt | Social Impact |

| Gillespie Economics | Economic Impact |

I have heard that you are building a lead mine but also silver. What is it?

As the names suggests, Bowdens Silver will be a silver mine. However, the mine will also produce a quantity of zinc and a lesser quantity of lead.

Why do you report silver, zinc and lead figures differently?

As previously reported to the CCC, to report elements in the same units is misleading and against convention and industry standard. Silver is a rare and valuable ‘precious metal’ while zinc and lead are common ‘base metals’. Industry standards are clear in that precious metals (e.g. gold, silver, platinum, palladium) are reported as grams per metric tonne while base metals (copper, lead, nickel, tin, zinc) are reported in percentage. It is industry standard in Australia that precious metals are reported in troy ounces and base metals in tonnes.

As a public company and an Australian Securities Exchange listed company it is compulsory to adhere the 2012 Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (‘the JORC Code’). The JORC Code is a professional code of practice that sets minimum standards for Public Reporting of Minerals Exploration Results, Mineral Resources and Ore Reserves. The Code has been adopted by The Australasian Institute of Mining and Metallurgy (’the AusIMM’) and the Australian Institute of Geoscientists (‘AIG’) and is binding on members of those organisations. The Code is endorsed by the Minerals Council of Australia and the Financial Services Institute of Australasia as a contribution to good practice. The JORC Code is regarded as a global standard.

As stated in the code, the principles governing the operation and application of the JORC Code are Transparency, Materiality and Competence.

– Transparency requires that the reader of a Public Report is provided with sufficient information, the presentation of which is clear and unambiguous, to understand the report and not be misled by this information or by omission of material information that is known to the Competent Person.

– Materiality requires that a Public Report contains all the relevant information that investors and their professional advisers would reasonably require, and reasonably expect to find in the report, for the purpose of making a reasoned and balanced judgement regarding the Exploration Results, Mineral Resources or Ore Reserves being reported. Where relevant information is not supplied an explanation must be provided to justify its exclusion.

– Competence requires that the Public Report be based on work that is the responsibility of suitably qualified and experienced persons who are subject to an enforceable professional code of ethics (the Competent Person).

The JORC Code requires an application of industry standard measurement tools and the quality of analysis to be used in reporting. It is convention and industry standard that an appropriate unit of measurement is applied. In the case of reporting valuable commodities where a small amount in a large sample is relevant, for elements such as precious metals, the industry standard is to use grams per tonne (or its equivalent parts per million). This similarly applies to bulk commodities or commodities where the number reported is required to be reported as a percentage of the overall sample. For example, iron-ore is reported often in the range of percentage as economic cut-off grades are generally around 40%. It would be non-industry standard and misleading to report iron ore results in grams per tonne as 40% is the equivalent of 400,000 grams per tonne. Similarly, for base metals, it would be non-industry standard to report in grams per tonne where, for example, 1 percent is equal to 10,000 grams per tonne.

In reporting totals of contained metal in Mineral Resources and Ore Reserves, the requirements are to report totals in the unit by which the metal is traded. Gold and silver and other precious metals are traded on markets throughout the world in troy ounces (for example Comex or Chicago). Zinc, lead and other base metals are traded as tonnes (i.e. on the London Metal Exchange).

In terms of production and based on draft optimisation works, Bowdens Silver’s revenue will have an approximate split of 70% silver, 18% zinc and 12% lead. This fundamentally classifies the project as a silver mine with zinc and lead credits. In terms of volume and again based on draft optimisation works, contained metal in concentrates will be over 50 million ounces of silver, 180,000 tonnes of zinc and 125,000 tonnes of lead for the life of mine. Without the silver, the zinc and lead would be sub-economic and hence not be a viable mineral deposit. The silver, on its own, accounts for the economics of the Bowdens Silver Project hence it is a silver mine development.

There have been factually incorrect comments purporting that the Bowdens Silver Project has substantial lead content. In fact, lead content at Bowdens Silver is very low.

Generally, Mount Isa and Broken Hill are base metal mines. i.e. they mine primarily lead and zinc in addition to quantities of silver. Mount Isa also contains substantial quantities of copper.

To put this into context approximate historical resource grades for Mount Isa and Broken Hill are shown below and in comparison to Bowdens Silver resource grades. For lead Mount Isa and Broken Hill lead grades are 24 times and 38 times the grade compared to that at Bowdens Silver.

| Zinc % | Lead % | |

| Bowdens Silver Grade | 0.38 | 0.26 |

| Historical Mount Isa Grade | 9.2 | 6.2 |

| Difference (x) | 24 | 24 |

| Historical Broken Hill Grade | 11.0 | 10.0 |

| Difference (x) | 29 | 38 |

The other major difference is that Mount Isa and Broken Hill historically had smelting facilities on site. (Mount Isa still does while Broken Hill’s smelting operations are now located at Port Pirie in South Australia). Pollution at these two operations was largely a result of old redundant smelting technologies rather than pollution from mining. Bowdens Silver will not have a smelter.

How big will the mine be?

The open cut pit will be approximately 68 hectares in size and the tailings storage facility (TSF) will be approximately 140 hectares in size. There will also be related infrastructure in proximity to these sites. The final footprint of the mine site (including roads, offices, workshops, etc) is still being developed as part of our definitive feasibility study.

The mine will process approximately 2.0 million tonnes per annum to produce concentrates for sale. Production of silver will average approximately 5.0 million ounces per year.

How does the mine compare to Mount Isa and Broken Hill?

Generally, Mount Isa and Broken Hill are base metal mines. i.e. they mine primarily lead and zinc in addition to quantities of silver. These mines produce over 20 times the amount of zinc and lead that Bowdens Silver will produce. Mount Isa also contains substantial quantities of copper.

The other major difference is that Mount Isa and Broken Hill historically had smelting facilities on site. (Mount Isa still does while Broken Hill’s smelting operations are now located at Port Pirie in South Australia.) Pollution at these two operations was largely a result of cold redundant smelting technologies rather than pollution from mining. Bowdens Silver will not have a smelter.

When will you stop adjusting the layout?

The layout of the mine is still undergoing design changes as part of the Definitive Feasibility Study which not only considers the optimal layout from an economic mining point of view but also takes into account environmental and community concerns and subsequent mitigation measures. Different layouts reflect the ongoing studies and planning processes.

Will the mine operate at night?

The final operating hours are still to be determined. It is proposed that the processing plant (where the ore will be crushed and the silver/lead and silver/zinc concentrates will be produced), will be housed in a sound proofed building that will operate 24 hours a day, 7 days a week. Actual mining operation hours are still being investigated as part of the EIS and will be determined by compliance with the relevant noise and environmental regulations. Over time, operating hours may occur at night due to factors such as the open cut pit deepening, providing an opportunity to create further noise mitigation infrastructure.

What is your policy for sponsorships? Who do you sponsor?

Bowdens Silver’s policy includes both direct donations and also longer term sponsorship activities. Our policy supports the following areas of interest:

- Community – support to improve social facilities such as the development of academic programs, infrastructure enhancements, improved amenity and environment and charities;

- Sport – support for sporting organisations which promotes team work, health and wellbeing and which benefit communities on a wider scale;

- Safety – support for organisations that provide rescue and emergency services and promote safe behaviour; and

- Arts and culture – support for projects in areas such as cultural heritage, ethnic and Indigenous cultural initiatives and community arts programs.

What community guidelines do you fall under?

The Exploration Code of Practice: Community Consultation, developed by the Department of Industry, Resources & Energy. Additional community guidelines form part of our Exploration Licence and Review of Environmental Factor conditions. With the impending EIS completion, our Community Consultative Committee will change to fall under the Department of Planning and Environment’s Community Consultative Committee Guidelines.

What is the Community Consultative Committee (CCC)?

The CCC comprises representatives from the local community, Mid-Western Regional Council, Bowdens Silver and an Independent Chair.

The purpose of the CCC is to strengthen community understanding of the project, provide a forum to present information on the project and its environmental performance, to address community concerns and to facilitate open communication between the communities, state and local government and Bowdens Silver during the exploration phase of the project. The CCC provides an opportunity for the company and stakeholder representatives to identify common grounds within the bounds of the project and seek positive social, environmental and economic outcomes. The CCC meets quarterly and the meeting minutes are displayed on the Bowdens Silver website.

What will happen to Bowdens Silver and the site if the proposal is not approved?

In the event that the project is not initially approved, Bowdens Silver will undertake to make the necessary modifications to satisfy any approval conditions or consents. Bowdens Silver will then re-submit the development approval.

Does the company plan to get mine approval then sell the site?

No. Bowdens Silver is committed to developing and operating the mine.

With no prior experience, how can we be confident in Bowdens Silver’s performance?

The community can be confident that Bowdens Silver will uphold and abide by all necessary performance criteria set out by the relevant authorities. We will be bound by Commonwealth, State and Local legislation.

In addition, Bowdens Silver currently employs and will continue to employ staff that have the necessary skills and experience to ensure the successful operation of the mine. Our team including our consultants have experience and success in exploration and development of mining operations throughout the world.

Who makes the decision for approvals?

Under Section 89(d) of the Environmental Planning and Assessment Act (1979), the NSW Minister for Planning is the consent authority for State Significant Development. The Minister will most likely delegate the consent authority function to the Planning Assessment Commission, which is to become the Independent Planning Commission at a later date in 2017.

What happens if the results from the specialists indicate that there will be an impact to the village?

A key objective of the EIS was to design a project that satisfied all environmental criteria with respect to noise, blasting, dust and water, all of which are based on health-related criteria and/or human comfort criteria at residences in the village. The assessments that were undertaken for each of these factors in the EIS nominated a range of design and operational safeguards to enable Bowdens Silver to meet these criteria.

How big is the mine compared to the coal mines?

In terms of productions rates, the Bowdens Silver mine will have much lower impacts. Our mine will produce 2 million tonnes of ore per year compared to nearby coal mines producing upwards of 14 million tonnes of coal per year.

Unlike coal, the geology of our silver resource means it does not run in long seams like coal does. The silver resource is essentially located only in the open cut pit location and mining will be concentrated in that area.

How big will the buffer zone be?

There are currently no requirements for a prescribed buffer zone around mining projects in NSW. A buffer zone normally relates to an area in which the noise and air quality criteria required for human health and amenity cannot be satisfied. The area would be determined as a result of specialist studies. Bowdens Silver’s objective is to ensure that the buffer zone is largely confined to land that the company owns.

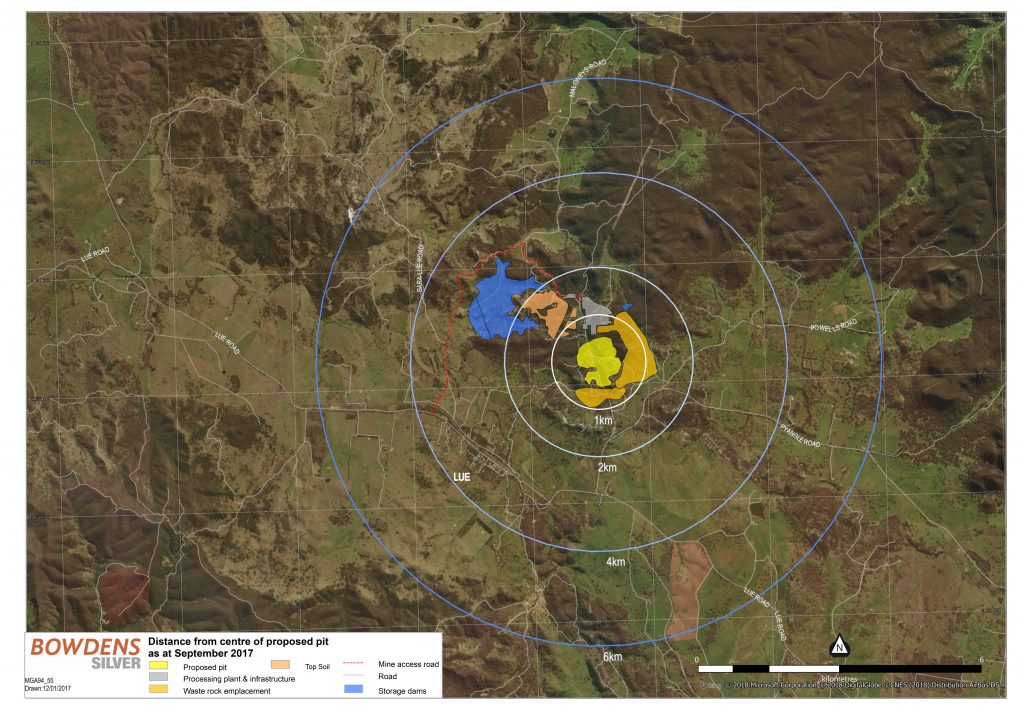

Where will the proposed pit be located?

The map below shows the location of the proposed pit and distances from the centre of it. The map also shows a draft of the mine site layout and infrastructure as at September 2017. Please note that infrastructure design is ongoing as part of the Feasibility Study and Environmental Impact Statement processes.

Please click on the map to enlarge.

Why isn’t it going to be 8km like the coal mines?

There is currently no requirement for a prescribed buffer zone around coal mining projects in NSW.

What is your policy on protecting the environment?

Environmental performance is critical to the success of any mining project. At Bowdens Silver we adhere to a strong environmental policy and environmental considerations are addressed at every stage of our activities.

The majority of our workforce live locally and we are committed to being a responsible and ethical corporate citizen able to hold our head high within our local communities. We are dedicated to ensuring that our environmental practices are best practice.

The basis of Bowdens Silver achieving this includes:

- Exemplary standards in commitment to all relevant legislation, regulations and other laws.

- Continual assessment and development of internal policies for the protection of the environment in collaboration with stakeholders, the community and regulatory authorities.

How much dust will there be?

The amount of dust that would be generated within the mine site is the subject of a detailed air quality impact assessment, to be completed once the location and type of activities and numbers/types of equipment are known. The air quality impact assessment will be conducted in accordance with the requirements of the NSW EPA, as specified in the “Approved Methods for the Modelling and Assessment of Air Pollutants in NSW.” Emissions of air pollutants will be quantified using NSW EPA-approved emission factors and equations. Calculated emissions will be input into an approved dispersion model, configured for local meteorology, terrain and land cover, to predict the extent of potential air quality impacts in the surrounding environment.

The NSW EPA document “Approved Methods for the Modelling and Assessment of Air Pollutants in NSW” specifies impact assessment criteria for air quality. These criteria are health-based and amenity-based to protect the health of the general community. The primary air pollutant that would be generated by the proposed operations would be dust (particulate matter (PM)). Different PM size fractions will be quantified – coarse (typically 10micron (µm) to 50µm) and fine (< 10µm and <2.5µm). Other pollutants to be quantified will include lead, individual metals and diesel fuel pollutants. For the majority of air pollutants, the air quality criteria relate to the total concentration in the air and not just the impacts from proposed activities on the mine site. In other words, background or existing levels will also be accounted for in assessing potential impacts relative to applicable criteria. Bowdens Silver is committed to controlling the quantity of emissions generated so that all air quality criteria are satisfied at all privately and publicly-owned residences.

What will be in the air from the mine and where will the dust go from the mine?

The primary air pollutant from the mine will be dust. The EIS has produced information on what material will be in the air as well as a series of maps showing the distribution of dust from the mine site.

How will you ensure people can sleep at night?

The Project will be assessed against the NSW Industrial Noise Policy (INP) and the associated INP Application Notes, which contains guidance on assessing sleep disturbance from industrial sites. The EPA conservatively nominates that the (external) maximum noise level from the mine site should not exceed 45dB(A) at one metre from the bedroom facade at privately-owned residences. A level of 45dB(A) is equivalent to a modern passenger car travelling on a sealed road 80m from a residence at a speed of 50km/hr. The EIS will need to demonstrate that the sleep disturbance criteria will not be exceeded and how that will be achieved.

Is the noise logger microphone omnidirectional? i.e. can pick up sound from all directions equally.

Yes.

How will operational noise compare to the rock breaker already audible from the village? Or from the pub?

The rock breaking activities recently conducted were at an elevated and exposed location and, whilst the noise level over a short period of time would have been >35dB(A) at some locations, this is permissible for exploration activities that occur over short periods where noise levels are permitted up to 40dB(A). The sources of operational noise on the mine site would invariably be positioned behind topographic or constructed barriers that would assist in attenuating noise generated by Project activities. In addition, during operations, percussive activities such as rock breaking are not expected to be required. If noticeable, mining operation noise is likely to be perceived as continuous mechanical and/or vehicle noise.

Would the mine consider moving the processing plant further north?

As part of our ongoing planning and feasibility studies, we are constantly updating and optimising our infrastructure plans. These decisions not only consider the economic benefits but also environmental and community considerations. Our most recent draft infrastructure plan has actually moved the processing plant further north and at a greater distance from Lue village. The final plan will be exhibited within the EIS.

What will happen downstream if there is an extreme weather event?

The objective of all Bowdens Silver’s water management planning and infrastructure on the mine site will be for the capture and management of runoff during rainfall events in order to prevent any uncontrolled discharge entering the downstream environment. Where appropriate, clean water upstream of disturbed areas would be diverted to maintain downstream environmental flows. The design rainfall event would be determined based on the nature of the contributing catchment. For example, at a minimum, the tailings storage facility would be designed to manage infrequent extreme rainfall events and prevent any discharge. Infrastructure for the capture and treatment of sediment-laden runoff from the mine site would be designed to capture frequent rainfall events with discharge to the downstream environment permitted only when the EPA specified water quality criteria are met.

Will the mine impact surface water levels and quality in Lawsons creek?

The mine site is being designed to minimise the extent of changes to flows in Hawkins Creek and Lawsons Creek. Minor flow reductions would occur however Bowdens Silver will endeavour to divert as much water around the mine site as possible to maintain downstream flows. The details of the mitigation measures and extent of changes to flows in the creeks will be presented in the Environmental Impact Statement.

With respect to water quality, it is Bowdens Silver’s objective not to adversely affect the water quality in either Hawkins or Lawsons Creek. This would be achieved through ensuring runoff from the mine site meets all criteria nominated in the mine’s environment protection licence.

How will Bowdens Silver manage Acid Mine Drainage?

Geochemical studies to establish the potential for acid generation at the mine site have been ongoing over a number of years. The objective of these studies is to classify the rock materials of the mine site based on their potential for acid generation. Once this information is known, Bowdens Silver will design and implement appropriate strategies to manage material with the potential for acid generation principally through encapsulation to isolate potential acid-forming materials.

How will you control cyanide from entering Lawsons Creek and affecting my water supply?

Bowdens Silver is presently investigating methods for the processing of the ore and currently there is no decision to use cyanide in the processing operations. If cyanide were to be used, it would be in very small quantities and would be destroyed in the processing plant. The storage and handling of chemicals or compounds required for use on the mine site would be conducted in accordance with any conditions of the development consent, environment protection licence, national standards, relevant guidelines and current industry best practice.

What contaminants are likely to be discovered in the air and water from the mine?

The existing air, surface and groundwater environment in the Lue area is a reflection of many factors including the soils, geology, vegetation and land uses of the area. In order to better understand the nature of this environment, Bowdens Silver conducts monitoring of the existing environment of the proposed mine site and the surrounding area to establish the nature of the existing environment over time and its response to natural variations. This information will be presented in the relevant sections of the EIS. It will be Bowdens Silver’s objective not to cause any adverse change to the existing environment outside of the mine site.

What options are you looking at for water supply?

Bowdens Silver is investigating a range of options for the supply of water. These include:

- Use of surface water runoff captured in existing dams on Bowdens Silver properties under the harvestable rights provisions of the Water Management Act;

- Advanced pit dewatering (extraction) of groundwater under licence from the relevant water sharing plan;

- Recycled water from the Tailings Storage Facility; and

- To secure water via commercial arrangements and agreements.

What is the Tailings Storage Facility?

The Tailings Storage Facility (TSF) is the structure where the residues from the processing of the ore are deposited. The TSF is a facility for the storage of waste from the processing plant. The TSF will be designed, constructed, operated and managed in a manner that meets NSW, Australian and international best practices.

How do you prevent contaminants leaching into the earth underneath the TSF?

Under NSW and Australian guidelines, the design of the TSF must consider the underlying geology as well as the nature of any potential seepage so as to incorporate design features that limit, manage and mitigate the potential for seepage. Geotechnical investigations are presently underway on the mine site to inform the design of the TSF.

What happens if the TSF leaks?

Routine groundwater monitoring in the vicinity of the TSF would form part of any operational strategy for the TSF. A primary objective of such a program is to provide for the early detection of any unanticipated changes in the existing groundwater environment so that further investigations and management actions may be taken. This will achieve Bowdens Silver’s objective of leaving the environment beyond the mine site unchanged.

How will you ensure my animals won’t drink from the tailings storage facility, become contaminated then cross contaminate when they die?

Stock access to the TSF would be prevented by the construction of robust and regularly maintained and monitored fencing.

How much cyanide will be used?

Bowdens Silver is presently investigating methods for the processing of the ore and no decision as to the type, nature and or volumes of process chemicals required has been made at this stage.

How much cyanide will end up in the TSF?

Bowdens Silver is presently investigating methods for the processing of the ore and no decision as to the type, nature and or volumes of process chemicals required has been made at this stage. If cyanide were to be used, it would be in very small quantities and would be destroyed in the processing plant.

What contaminants will actually go into the TSF?

As noted above, no decision as to the type, nature and or volumes of process chemicals required has been made at this stage. Any residual chemicals not fully consumed in processing would be stored in the TSF.

How many trucks per day?

Although yet to be confirmed, the mine will be producing approximately 20,000 tonnes of concentrate per year. To transport this would require 3-4 trucks per day. This is higher than initially communicated primarily due to adjustments in concentrate production assessments.

How will you ensure responsible truck driver behaviour and road safety?

All staff and contractors undergo an internal induction which highlights safety issues such as traffic speed and driver behaviour. Regular safety meetings reinforce these messages. Any behaviour that falls outside of expectations is dealt with via stringent internal disciplinary processes.

Contractor companies will be held accountable by Bowdens Silver for the conduct of their personnel whilst performing contract work, via contractual terms.

How will you decide where the road will be located?

The realignment of Maloneys Road will involve a number of different decisions and factors. Stakeholders will include but not be limited to community members, Mid-Western Regional Council, Roads & Maritime Services, relevant engineers and company representatives. At the recent Community Information Session at Lue Hall we listened to and captured quality feedback from the community on their recommendations and preferences. As our plans progress, we will continue to involve the community in these plans.

Is there a plan to move the rubbish tip?

During the realignment of Maloneys Road, there may be an opportunity for Bowdens Silver to provide a better and safer location for the waste transfer station. Our initial thinking is that we may be able to locate the tip on Bowdens Silver owned land. This would provide a safer entry and exit point for users and a better visual aspect than its current location, and an opportunity to create a more efficient and organised waste depot. The Mid-Western Regional Council will need to be consulted during the process and approve any moves and/or development.

Will Bowdens Silver seal the access road?

Yes, the road will be sealed. It will be the major access point for staff and contractors and as such, will need to accommodate a regular and consistent traffic flow. Sealing the road will also be safer and minimise noise and dust.

What is involved in the rehabilitation process?

Rehabilitation will be a progressive process whereby areas or landforms created on the mine site in their final or interim form will be reshaped and revegetated. This process is intended to limit erosion, dust lift-off and to minimise visual impacts. The process will involve shaping with earthmoving equipment, placement of subsoil and topsoil and seeding/fertilising or tube-stock planting. At the end of the mine life, most disturbed areas would be shaped and vegetated. Fixed plant and infrastructure would be removed and all landforms rehabilitated and revegetated in a manner suited to an agreed future land use (e.g. grazing, nature conservation). Final landforms created above the waste rock and tailings would be capped and vegetated to create geotechnically and geochemically stable, safe and non-polluting features. The open cut pit void would remain with groundwater levels equilibrating over time. An indicative final water level would be presented in the EIS.

Will you fill the void?

The mine closure plan is still being developed as part of the EIS however, the open cut pit is likely to remain a void that will fill with water.

Who will pay for rehabilitation?

The Division of Resources and Geoscience (within the Department of Planning & Environment) will determine rehabilitation bonds which the company will be required to lodge prior to the commencement of mining. A comprehensive rehabilitation plan is currently being developed and it will be available for public discussion when the EIS is lodged.

What happens with all the land you have purchased? Will you continue to run a farm?

Bowdens Silver owned land that is not being utilised as part of the mining operation or as biodiversity offset will continue to be farmed. We currently run a mix of cattle and sheep. The farm will also continue to operate the necessary weed, pest and vermin controls necessary of any land manager.

Will Bowdens Silver make sure their properties are maintained e.g. cattle grids?

Yes, the properties will continue to be regularly maintained. Bowdens Silver employs a full-time farm manager who ensures appropriate stocking rates and conducts the necessary weed and pest eradication programs as well as maintaining fencing, gates and cattle grids.

What is happening with all the houses you own?

We have renovated some of the houses to a habitable standard and are utilising them for contractor accommodation, visiting consultants and long-term and short-term staff accommodation. The majority of the houses have been rented to members of the public to encourage residents to move to, or to continue to live locally.

Will the wind roses be available in the EIS?

Annual and seasonal wind roses (diagrams that show wind direction and speed) will be presented in the EIS and supporting documents together with vector diagrams to explain how the wind direction changes around the topography in the Lue area.

Will the company provide weather data?

Weather data is currently available live from our two weather stations via our website. There is also considerable historical weather data on the website.

What health effects will people be exposed to from the mine?

We can’t answer this yet. This is what the assessment will be evaluating.

The development would not be approved if it resulted in adverse health effects in the community.

Will the mine will result in lots more people on dialysis?

The health assessment has not yet been undertaken, however the development would not be approved if it had the potential to result in adverse health effects in the community.

Would it be safe to live 10-15km from the mine?

The health assessment has evaluated impacts to the whole community. The development would not be approved if it resulted in adverse health effects in the community no matter how close.

Will the school have to close due to the mine?

No. The health assessment has evaluated impacts to all members of the community, including children attending the school.

The development would not be approved if it resulted in adverse health effects in the community.

Will our rainwater tanks and drinking water quality be compromised?

This has been evaluated in the health assessment and all information is contained in the EIS.

Will you be testing our rainwater tanks?

Some testing has already been conducted to see what the quality of water is without the mine. Further testing will occur and in particular once the mine is operational.

Can any exposure to lead compromise our health?

We are all exposed to lead in our daily lives as it is a naturally occurring element, present in soil, water, food products (and others). Assessment of health effects associated with lead exposure are based on studies of blood lead levels. The research on low level exposures to lead has not clearly identified what level is safe and what is a level of concern. The most current detailed review by the NHMRC (National Health and Medical Research Council) identified the following:

- A blood lead level greater than 5 micrograms per decilitre (µg/dL) is considered to represent exposures that are above the average background level in Australia. Exposures to low levels of lead that result in this background level are unavoidable

- Exposures below 5 µg/dL have been associated with effects on cognitive function and IQ, however these studies did not provide clear association with lead exposures due to confounding factors (socioeconomic status, education, parenting style, diet and other exposures)

- Exposures above 5 µg/dL, and less than 10 µg/dL have been associated with behavioural effects in children, delays in sexual maturation or adolescence, increased blood pressure and risk of hypertension in adults and pregnant women. Where this occurs, the advice is that that exposures that result in blood lead levels above background should be identified and removed or minimised

Will you be testing people’s blood for lead?

This is expected to be undertaken, before and after operation of the mine. It is important to test before the mining operations commence to establish existing background levels within the community.

What about the other metals, is Bowdens Silver assessing these?

A comprehensive Health Risk Assessment, separate to the Lead Impact Assessment has been prepared to support the Environmental Impact Statement. This study addresses existing and proposed levels of metals and metalloids in the environment.

We see you are involved with local schools. Why?

Bowdens Silver has a strong education focus not only internally but with external educational institutions. We believe in providing educational opportunities not only now, but also into the future. We have donated items needed by the schools, as well as labour, and have provided excursion opportunities for local school students. Current activities and support are occurring with Lue Public School, Kandos Public School and Kandos High School. Other support activities are currently being planned.

How many people work at the site now?

Currently, Bowdens Silver employs 16 people with almost all living in the local area. Added to this are a team of drilling contractors and numerous consultants who visit and work on site on a regular basis.

How many jobs will you create?

During the construction phase, peak job numbers will be approximately 320. During mining operations, this number will move towards approximately 228 full time employees. In addition to every job created within the company, approximately two more jobs will be created through the use of local services and professional groups

Will you employ local people?

Yes. We wholeheartedly believe in providing job opportunities for locals wherever possible and we expect the majority of employees will be locally sourced and trained.

What training programs will you be offering for locals?

As the mine develops, we will look to provide a number of different training options for locals. This may include site-based traineeships, apprenticeships and structured, on the job training for less skilled roles. For technical roles, there may be opportunity for graduate based programs. Active training programs are in place for current employees.

Will I see the mine from the Lue village?

No. Bingman Hill provides a very good visual buffer between the village and the mine and all mine infrastructure.

After the mine is built will there be ongoing information for locals?

Definitely. Communication and information options will comprise a mixture of personalised meetings, emails, mailouts and newsletters, website updates, CCC meetings, information sessions and open days. We will continue to maintain an open-door policy for all interested parties.

What are the advantages for Lue and the surrounding towns?

There will be significant economic benefit to the local communities. This will occur through increased job opportunities leading to long-term employment. Financial benefits will also be seen through the use of local contractors and businesses which ultimately means more money being spent in the local economy. Educational opportunities will also form a part of our operation moving forward which will engage youth at an early stage about local learning opportunities.

Our decision not to build an on-site worker’s accommodation camp will also mean that workers will reside in local villages and towns, providing a boost to the local economies and the real estate market.

Bowdens Silver will continue to also provide appropriate partnerships and sponsorship opportunities for local events and organisations to ensure they can continue to function and expand. As the development progresses, so too will our ability to provide financial and volunteer services within the community.

Will we end up like Wollar and other coal mine areas?

No. The silver resource does not encroach near the village of Lue. We maintain that Lue will continue to be a village that people want to reside in, do business in and socialise in.

Will you eventually be buying out and closing the village?

No. We believe that Lue will continue to thrive and be a viable village into the future.

What do the blue lines on the Air Quality Assessment Maps mean?

The blue lines on the top two panels are contours displaying the lines of equal PM10 concentrations attributable to the activities undertaken within the Mine Site. The contours display higher concentrations, e.g. 25µg/m3 and 10µg/m3 near the dust-generating sources and lower concentrations away from the Mine Site. The contours on the panel in the bottom left hand corner display the lines of equal PM10 concentrations attributable to the activities within the Mine Site together with the existing background levels.

What do the blue lines on the Predicted Noise Level maps mean?

The blue lines on the four panels are contours displaying the lines of equal noise levels attributable to the activities undertaken within the Mine Site. The thicker blue line on the top left hand panel is the 40dB(A) contour noise level which is the criterion set by the EPA for daytime noise. The thicker blue line on the remaining panels is the 35dB(A) contour noise level which is the criterion set by the EPA for evening and night noise.

What “Mitigation Measures” will be used in relation to noise?

Bowdens Silver will adopt a range of mitigation measures to manage noise, including the

following.

• The use of noise attenuated mobile equipment with broadband style reversing

alarms.

• Full or partial enclosures to the noisier items of equipment within the processing

plant and the use of mid-high frequency noise conveyor alarms.

• A range of constructed barriers and embankments adjacent to the on-site haul roads

and optimised haul routes during the evening and night-time operations.

• Will be scheduling of operations to limit noise generation.

Full details have been itemised in the exhibited EIS.

Surface Water – How much clay and where will it come from to line the TSF floor?

Bowdens Silver anticipates that, based on the results of preliminary geotechnical drilling and soil investigations undertaken for the EIS, sufficient clay material is present within the footprint of the TSF. This would be confirmed during further geotechnical drilling investigations and an assessment of the engineering properties of the clay material present that would be undertaken to inform the detailed design of the TSF. Any shortfall in this material volume would be recovered from other disturbed areas within the Mine Site.

What is the predicted increase in salinity of the water drawn and returned to the TSF?

There would be no increase in the salinity of water drawn from and returned to the TSF. Geochemical analyses of tailings / water slurries identified electrical conductivities in the order of 700µS/cm. As these results were derived from tailings generated by the bench scale testwork program undertaken to inform the processing plant design, this is considered to be a reflection of the electrical conductivity of the water that would be drawn from and returned to the TSF.

If the salinity of the water in the TSF and complete mine water system increases above acceptable guidelines, what plans would be implemented to reduce the levels back below acceptable limits?

Part of the water supply for the processing circuit would be drawn from a system comprising water collected in the lined TSF and lined leachate management dam. This water system would be a “closed circuit” with no operational discharge proposed from either the TSF or the leachate management dam and therefore the only applicable guideline values for salinity would be with respect to acceptable tolerances within the processing circuit. This notwithstanding, the anticipated electrical conductivities of TSF decant 700µS/cm) and leachate (800µS/cm) are similar to the 75th percentile of the results for electrical conductivity recorded in Hawkins Creek, downstream of Price Creek (between 810µS/cm and 820µS/cm) and below those recorded for Lawsons Creek (between 1 180µS/cm and 1 400µS/cm), as part of the Bowdens Silver’s background surface water monitoring program. It is noted that the 75th percentile of current background results noted above all exceed the electrical conductivity trigger values for the Macquarie-Bogan catchment (30µS/cm – 350µS/cm), as established by the NSW Government.

What is the predicted seepage of water into the water table from the upper reaches of the TSF?

The results of Bowdens Silver’s background groundwater monitoring program suggests that groundwater in the upper reaches of the southern headwater of the TSF generally flows from east to west (i.e. mimics the topography) and, as the TSF would be a “down valley” type facility, once pumped into from the points located in the upper reaches of the TSF, tailings (solids and liquid components) would flow downstream towards the TSF embankment (i.e. in a similar direction), thereby lowering the risk of seepage from the upper reaches. The decant pond would form adjacent to the TSF embankment and this area would have the highest hydraulic (seepage) potential. However, the upper reaches of the TSF (where the potential for seepage is less) would also be lined where appropriate with compacted clay to further reduce the risk of seepage and meet regulatory standards.

Is all the external run off from the waste rock embankments and noise bunds captured and pumped back to site?

All mining-related infrastructure, such as noise barriers, flood protection bunds and waste rock embankments would be constructed using non-acid forming waste rock and soil. In most cases the external areas would be revegetated to limit sediment generation although it is recognised that some areas would have exposed rock as flood protection. Any runoff from the external faces of this infrastructure would be managed using stormwater management infrastructure (eg erosion and sediment control) designed in accordance with regulatory guidelines. Stormwater captured within this infrastructure would be treated to meet any conditions imposed under the Mine Site’s Environmental Protection Licence issued by the NSW Environment Protection Authority prior to release (if required). It is noted however that, as a landholder, Bowdens Silver is entitled to capture and use the volume of runoff allowable under the maximum harvestable rights provisions of the Water Management Act (2000). Within the Mine Site, all internal runoff that has been in contact with potentially reactive material (eg potentially acid forming waste rock placed in the waste rock emplacement) would be captured in lined facilities for recycling in the processing circuit and not discharged to the environment.

Is there is an extensive drainage and pumping system designed to handle any and all external water run off collected from these drains?

The “closed circuit” system of the TSF and leachate management dam would be hydraulically connected via a pump and pipe system. Runoff from clean areas would be diverted around disturbance by suitably sized drains whilst potentially sediment-laden runoff from external areas would be managed in accordance with current regulatory practice and the conditions of the Mine Site’s Environment Protection Licence issued by the NSW Environmental Protection Authority prior to release (if required).

Will it [the TSF] handle extreme rain fall events?

The “closed circuit” system would be designed and operated in a manner to cope with “infrequent” rainfall events (i.e. 1:100 annual exceedance probability). It is noted that, over the proposed 16.5 year Project-life, the probability of such an event occurring is 15% and less for events rarer than 1:100 annual exceedance probability. The effectiveness of the “closed circuit” water management structures in capturing and containing runoff would also be improved by the return of water from key structures to the processing circuit or at worst, to the main open cut pit sump.

Is there a filtration system proposed to clean water before any water is "returned" to Hawkins and Lawsons Creeks?

As noted above, potentially sediment-laden water would be captured, stored and treated prior to release in accordance with current regulatory practice and the conditions of any Environmental Protection Licence issued by the NSW Environmental Protection Authority. The anticipated means of treating this water would be detention over time although the use of flocculants may also be considered, as required.

Groundwater Assessment – In regards to the “Maximum Groundwater Drawdown” map what effect will a predicted draw down of 5-10m have on wells, bores, and farm dams?

With respect to groundwater bores and depending on the nature of the bore (e.g. depth of screen and pump), drawdown between 5m to 10m may affect bore productivity. It is noted that in the course of the Groundwater Impact Assessment for the Project, no registered, privately-owned groundwater bore has been identified within the predicted 5m to 10m drawdown contour.

Is there modelling available showing the drawdown effect on the Hawkins and Lawsons Creeks?

The Groundwater Impact Assessment for the Project prepared by Jacobs considered it likely that the waterholes of Hawkins Creek, which only flows intermittently, are sustained by groundwater inflows. Despite its larger catchment area, Lawsons Creek, which was known in Wiradjuri as “Loowee” (chain of waterholes) also displays a similar condition in the vicinity of the Mine Site Groundwater modelling identifies that overall the groundwater contribution to streamflow in Hawkins and Lawsons Creeks in the vicinity of the Mine Site is relatively low. The modelled groundwater contribution to Hawkins and Lawsons Creeks was calibrated using data collected at two flow gauges installed in Hawkins Creek and monitored by Bowdens Silver.

As established by Bowdens Silver’s groundwater monitoring program, groundwater levels in the vicinity of the Mine Site currently vary as the result of rainfall variations over time and these natural variations in groundwater level currently impact groundwater inflows to waterholes should the groundwater level fall below the bed elevation of the waterhole. The EIS will include details showing any areas where predicted drawdown would lead to a drop in the average groundwater level, beneath the bed elevation of the watercourse as a result of the Project.

Mine Site Rehabilitation – What year do you expect to be able to start pushing topsoil onto the TSF surface to commence rehabilitation?

The surface of the TSF would be progressively rehabilitated through the placement of a designed cover system comprising a geosynthetic clay liner1, compacted subsoil, sized nonacid forming waste rock and topsoil. ATC Williams advise that it would be possible for rehabilitation to commence within the last 6 months of the TSF’s operation in two of the three entries. It is further noted that a trial TSF rehabilitation area would be established early in the Project life to determine the optimum ratio of the above materials prior to the commencement of the rehabilitation of the TSF surface.

Visual – Where is the modelling for lighting pollution?

The lighting assessment undertaken for the Project adopts a methodology that addresses the requirements in Australian Standard AS/NZS4282 where a range of light technical parameters such as vertical illuminance, threshold increment, upward light ratio and luminance intensity are considered. Details of the approach to the lighting assessment have been included in a standalone report supporting the EIS.

How much water are you taking from the Lawsons Creek Valley?

This question was directly raised by a community member but has been asked by other community members concerned about water availability and security for the Project. The Lawsons Creek Valley is for the purpose of this response considered to cover the Lawsons Creek Catchment. It is important to recognise that the Project would not directly source any water from Lawsons Creek. In fact, arrangements have been made to construct a water supply pipeline to avoid the need to use water from local sources in this manner.

The Surface Water Assessment for the Project prepared by WRM Water and Environment discusses the Lawsons Creek Catchment (see Section 3.4 and Figure 3.4 of WRM, 2020). WRM notes that Lawsons Creek has a catchment area of approximately 507km2 to the Cudgegong River confluence (near Mudgee). However, for the purpose of assessment, an area of 272km2 has been considered which is the catchment area to the confluence with Walkers Creek. At its peak, the catchment of the Mine Site would cover 550ha or approximately 2% of the catchment area to the confluence with Walkers Creek (this may be compared with total surface disturbance of 422ha). The bulk of the much larger Lawsons Creek Catchment has been altered (cleared) to support agricultural activities. While higher flows may be expected given the large size of the catchment, the majority of this water is captured on farm dams or diverted. It is also worth noting that historic agricultural activities have impacted water quality in Lawsons Creek. Average flows in Lawsons Creek downstream from Hawkins Creek are estimated at 7 136ML per annum.

The water supply requirements for the Project and volume of water that would be sourced from within the Mine Site are presented in detail in Section 5.5 and Table 5.5 of WRM (2020). In summary, the modelling undertaken by WRM estimates that an average annual input of 1,526ML of water would be sourced from the Mine Site which includes water sourced from capture of rainfall, from groundwater bores or inflow to the main open cut pit and moisture contained in the ore materials. A large component of the water required would be sourced from groundwater or runoff that does not enter Lawsons Creek and therefore is not a direct impact to creek condition. The loss of water attributable to the Project that would otherwise flow to Lawsons Creek is 88ML per annum at a peak (downstream of the confluence with Hawkins Creek) or 1.2% of annual flow in this location. Downstream of the Walkers Creek confluence, the quantity of water that would otherwise flow to Lawsons Creek would be 188ML or 2.2% of annual flow in this location (see Section 8.4 and Table 8.1 of WRM, 2020).

It is worth noting that Bowdens Silver has focused on opportunities for water reuse and recycling on the Mine Site through the capture and use of sediment‑laden water in dams, groundwater and surface water that accumulates in the open cut pit and decant water from the TSF. 40% of all water used would be recycled for use in processing and other site requirements. It is stressed that Bowdens Silver has prioritised use of water that would be sourced within the Mine Site as this is water that would need to be managed on site regardless of its final use and therefore it is considered beneficial use of the water available. For example, the groundwater inflows to the open cut pit occur as the ore material is extracted and the water needs to be managed to permit ongoing extraction. This water would be pumped to the raw water dam and used in processing as a preference over water supplied externally. In this manner, every effort has been made to be efficient with water use and where it is sourced, provide for multiple sources so there is contingency in the system and reduce reliance on water that may otherwise be used by landholders within the Lawsons Creek Valley.

Further information on the licensing requirements and site water balance may be found in the recorded presentation summarising the outcomes of the Surface Water Assessment available from the Bowdens Silver Website. Michael Batchelor of WRM directly responds to a similar question in that presentation.

How many times have you visited Bara Road, and at what time of year (regarding the orchids)?

The field survey was undertaken by the ecology consultant in April 2019. Two species of threatened orchids were identified as requiring further assessment at the time. The survey that followed did not detect presence of the orchids in the area, nor are there historical records of presence in the area. It was noted that one of the orchid species is sensitive to the effects of grazing, indicating presence is unlikely. The consultant concluded that these orchid species are unlikely to be present in the area, and no further assessment was necessary.